China Sand Mobile Portable 2 mm Vibrating Grizzly Screen Equipment Mesh Sieve Machine Separator 3/4 Deck Vibrating Screen Application for Coal Laboratory Price

China Sand Mobile Portable 2 mm Vibrating Grizzly Screen Equipment Mesh Sieve Machine Separator 3/4 deck Vibrating Scree

Basic Info

| Model NO. | Hengchang - Vibrating Screen |

| Running Track | Circular Vibrating Screen |

| Supporting Device | Coil Spring |

| Warranty | 2 Years |

| Customized | Customized |

| Condition | New |

| After-sales Service | Video Technical Support, Engineers Available to Se |

| Product Name | Circular Vibrating Screen |

| Motor | China Famous Band |

| Installation | Under Engineer′s Guide |

| Aftersales | Installation, Training, Skill Instruction |

| Material | Carbon Steel |

| Color | as Your Requirement |

| Transport Package | Standard Packing |

| Specification | as the different model of Circular Vibration Scree |

| Trademark | Hengchang |

| Origin | China |

| HS Code | 8428399000 |

| Production Capacity | 300 Set/Sets Per Month |

Product Description

China Sand Mobile Portable 2 mm Vibrating Grizzly Screen Equipment Mesh Sieve Machine Separator 3/4 deck Vibrating Screen Application For Coal Laboratory PriceProduct Information

| Yk Series of Vibrating Screen is also referred to as circular vibrating screen because its movement is approximate to be a circular motion.This series is especially designed for quarry stone.and it can be also used for separating and screening products in coal dressing,mineral processing. building materials,electricty and chemical industy.We have multi-mesh screen to screen materials with different sizes. |

| Brand | Type | Capacity | Screen Size | Max.feed size |

| Huahong | circular vibrating screen | 5.5-37t/h | 3-100mm/5-150mm | 400mm |

| Applications | 1.High frequency vibrating screen adopting latest technology is a kind of high-efficiency vibrating screen.2.This Series Circular Vibration Screen is of circular movement and designed for screening the ashlars in the stone pit. And it can also be used for classification in the coal selecting, ore selecting, building materials, electrical and chemical fields. | |||

| Brief Introduction | 1.This series of screening machine mainly make up by screen box, screen, vibrator, shock absorber spring device, chassis and other components.2.The vibrator is mounted on the side panel of the screen box and driven by motor through coupling rotation to produce the centrifugal inertia and force the sieve to vibrate. | |||

| Features | 1.The motor adopts type coupled axle machine, prevent the motor being wore for twisting when it is starting.2.Adopt rubber spring, the whole machine's operation is stable and reliable, the operating life is long.3.Adopt combined exciter and cardon movement, to assure the operation simultaneous, exclude the phenomenon of bearing affecting the operating life as its coaxial degree is not very good.4.Adopt air-cooling craft, reducing the bearing temperature, prolonging the bearing temperature, prolonging the bearing's operating life.5.Adopt high-strength bolted combination craft; make the sieve body's operating life more durable under the full vibration. | |||

| Model | Screen specification(mm) | Layers | Feeding size(mm) | Capacity(t/h) |

| 2YZK1237 | 3700x1200 | 2 | 3-50 | 30-100 |

| 3YZK1237 | 3700x1200 | 3 | 3-50 | 30-100 |

| 2YZK1548 | 4800x1500 | 2 | 3-100 | 30-275 |

| 3YZK1548 | 4800x1500 | 3 | 3-100 | 30-275 |

| 2YZK1848 | 4800x1800 | 2 | 3-100 | 56-330 |

| 3YZK1848 | 4800x1800 | 3 | 3-100 | 56-330 |

| 4YZK1848 | 4800x1800 | 4 | 3-80 | 56-330 |

| 2YZK1860 | 6000x1800 | 2 | 3-100 | 65-586 |

| 3YZK1860 | 6000x1800 | 3 | 3-100 | 65-586 |

| 4YZK1860 | 6000x1800 | 4 | 3-100 | 65-586 |

| 2YZK2160 | 6000x2100 | 2 | 3-100 | 81-720 |

| 3YZK2160 | 6000x2100 | 3 | 3-100 | 81-720 |

| 4YZK2160 | 6000x2100 | 4 | 3-100 | 81-720 |

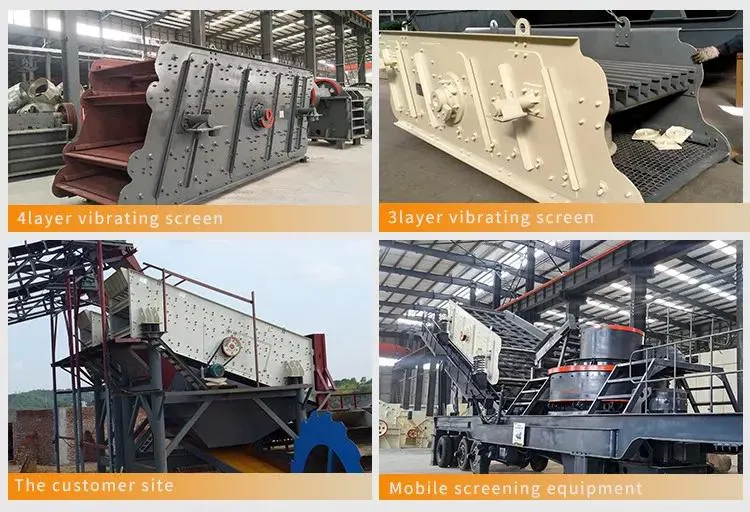

Products Details

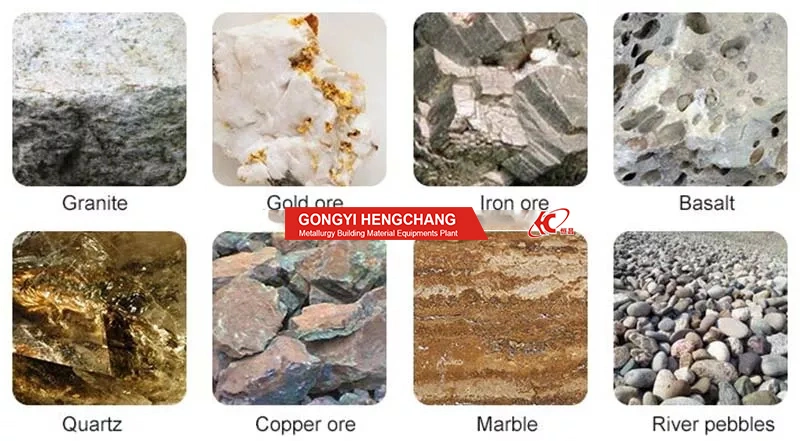

Vibro Sand Separator Machine Coal Gold Gravel Silica Sand Circular Vibrating Screen can be featured with 2 layers, 3 layers, 4 layers. It is used to sort and classify the materials accoding to the particle size by its circular vibration. Modular structure allows users to change the spare parts and handle the maintenance activities easily.Input Size: 0-200mmCapacity: 45-900TPHMaterial: Granite, marble, basalt, limestone, quartz, pebble, copper ore, iron ore and so on |

Working Principle

| Mining ore screen grizzly quarry vibrating feeder price dual eccentric shaft exciter generates excitation force. A gear pair-connects the two eccentric shafts, enables the shafts rotate to opposite direction with same speed. Through motor driving, the excitation force generated constantly, the material slides and bounces ahead to crusher on the feeder groove. When material go through the feeder's grid bars, the smaller material will fall down through the gap between grid bars and be sent to next crushing process. It enables the feeder to pre-screen material and fully ensures the crushing plant's high crushing efficiency and capability. |

Application Field

| Quarry, crawler sand, dry mortar, mechanism sand, power plant desulfurization, quartz sand, etc.Two kinds of vibrating screen sieve : manganese steel wire, polyurethane. |

| Suitable Material:Pebble, granite, basalt, iron ore, limestone, calcite, quartz and diabase. |

Company Information:About HENGCHANGHengchang headquarters is located in the industrial park in Gongyi City. It covers a total area of 150,000 square meters, including 100,000 square meters of standarized workshop. There are more than 200 sets of various large and medium-sized metal processing lathe, riveting machine, welding equipment and assembly equipment.We have more than 300 workers, including more than 20 middle and senior technicians. Hengchang is mainly focus on 4 series products: stone crusher machines, sand making equipment, powder grinding mills, mineral processing equipment and their spare parts. Every year,Hengchang can turn out 1,000 sets of crushers and 10,000 tons of crusher parts.

Customer Case

The Vibro Sand Separator Machine Coal Gold Gravel Silica Sand Circular Vibrating Screen with circular motion is specially designed for quarry to separate crushed stone material into different sizes, and is also used as a grading machine in coal dressing, ore dressing, construction material, electric and chemical industries.

Our Service

Before-sale services:

We guide customers to choose the best and applicable device; provide the advanced, energy-saving and practical technological processes, as well as we are responsible for the planning and design of the site.Sale services:Products must be inspected strictly before being sold; customers are invited to simulate and test machine on-the-spot and raise objections; in accordance with the agreements stipulated in the contract, we will arrange delivery.After-sale services:Our Company will send professional engineers to guide device installation, debug and train operators until customers are fully satisfied. Moreover, we will design and produce machines according to the special requirements of customers.Solemn Promise:The quality guarantee period of machines is one year except the wearing partsTips:The prices in the web only to be reference,according to raw material's price fluctuations; Specific price is subject to the negotiation.Packing &DeliveryPackaging Details:Normally the machines are taken apart before delivery and are packed by suitable packing ways, the packing ways are as below: Nude packing. Bundle packing. Grass rope packing. Water proof packing. Wooden pallets packing. Wooden box or carton box packing.Delivery Time:We will customize according to the actual needs of customers. Senior designers start to design the plan. After receiving the deposit, we will complete the delivery within 15 to 25working days.

Q:Why we believe in Gongyi Hengchang company?

A:1.More than 28 years' experience. 2.Hengchang is the leading professional supplier of solution, equipment's and service for crushing and grinding industry. 3.Products achieved ISO9001:2000 quality management certificate and EU CE certificate

Q:Delivery time ?

A:The lead time is 10-20 days, Delivery time will vary depending on the type of the machine, shipping method selected and part availability. Q:Payment terms ?

A:Accepted Payment Type: T/T, L/C, Western Union, Cash and so on. After sign the contract, pay the 10%-30% deposit of total purchase price and pay the full payment before delivery. Q:What will you do if the machine is broken down?

A:The Products warranty is one year. We will provide the technical advice and find the solution immediately for you when the machine is in trouble. For those wear parts, we guarantee the high quality parts for long-term supply. Q:What should i do if I want to get a best quotation?

A:If you want a suitable type for you, please let us know your material and capacity.

Send to us