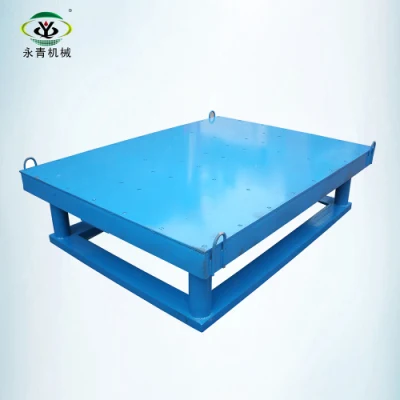

Laboratory Electric Vibrator Test Sieve Shaker

Basic Info

| Model NO. | AM-1S |

| Usage | Vibration Testing Machine |

| Type | Electrical Testing Vibrating Equipment |

| Screening Particle Size | 0.028-0.3mm |

| Layers | 1-8 |

| Certification | ISO 9001:2000 |

| Noise Level | Less Than 50dB |

| Material | Stainless Steel |

| Transport Package | Standard Export Package |

| Specification | According to actual situation. |

| Trademark | ACME |

| Origin | Hubei |

| Production Capacity | 1000pieces/Year |

Product Description

Product Description:

Our test sieve shaker, as a standard lab sieving machine, can be used for grading powder and granule, and filtering fluid in laboratories and testing rooms. With this filtering device, you can precisely analyze the granularity and powdery materials, and determine the solid content and impurity content in fluids.

Technical parameters of electric filter:

1. Motor power: 60W

2. External dimension: 350mm * 333mm x 203mm

3. Work power: AC220V 50Hz

4. Machine weight: 12kg

5. Maximum sieve amount: 500g

6. Screen level: 3 floors

7. Screen size: 100mm

Rotation speed: 115 plus or minus 5r/min

9. Reversal time: 60, plus or minus 2, s / 60 or plus or minus 2 % s

steps

1. Select the sieve layer corresponding to the inspection item according to the inspection standard after matching with the grain selection screen.

2. After the power supply is connected, the selected sieve layer should be set in order, and the sample should be included in the sieve. The screen cover shall be covered, and the tray will be put into the tray and tighten the rod.3. According to the start switch, the electric filter is automatically switched to the positive and negative program for each 1min and stops.If you need to select another sample after pouring out the sample, place the sample in the sieve and press the start switch.

4. Take out the sieve layer and pour the sample into the sample tray and test according to the rules.

Note and common troubleshooting

1. The instrument should be placed on the hard surface of the laboratory, which is dry and ventilated, to prevent the shaking from working.

2, sample after placing mesh cover, must tighten rod, to make smooth screen layer is firm in tray, then press the start button, pull rod under not tighten rod or not take before, do not press the start button.

3. Always pay attention to the two ends of the connecting rod of the connecting rod to prevent loose vibration and noise.

4. Three point connecting rod displacement, when the tray card dies, check the screw loose of the three connecting rod ends and adjust each one by one.

When the gearbox card dies, loose the central screw of the tray and the 3-m4 screw at the end of the three branches, adjust the gearbox.

Our Service:

1,We will provide all the details to you during the massproduction2,Customize your mould according to your need if have considerable orders3,Your requirements and complaints are highly respected

Certifications: