Tintungsten Manganese Aluminum Gold Chrome Tin Gravity Separator Jig with Ce Certification

Basic Info

| Model NO. | LTP/LTA/2LTC |

| Type | Gravity Separator |

| Voltage | 380V |

| Weight | <1T |

| Material | Stainless Steel |

| Material Feature | Heat Resistant |

| Certification | ISO9001:2008, ISO9001:2000, CE |

| Energy Saving | Energy Saving |

| Warranty | 1 Year |

| Color | Multi Color |

| Customized | Customized |

| Condition | New |

| Name | Tintungsten Manganese Aluminum Gold Chrome Tin G |

| Keywords | Crypto Mining Equipment |

| Installation | Engineer Guide |

| Usage | Gold Separating |

| Price | Negotiation |

| Spare Parts | Supply for Whole Life with Good Price |

| After Sale Service | Life-Long Service |

| Item | Mining Equipment |

| Power | 1.1kw |

| Rooms | 2 |

| Transport Package | Wooden Case |

| Specification | LTP-34/2 |

| Trademark | hengchang |

| Origin | China |

| HS Code | 8474100000 |

| Production Capacity | 10 Set/Day |

Product Description

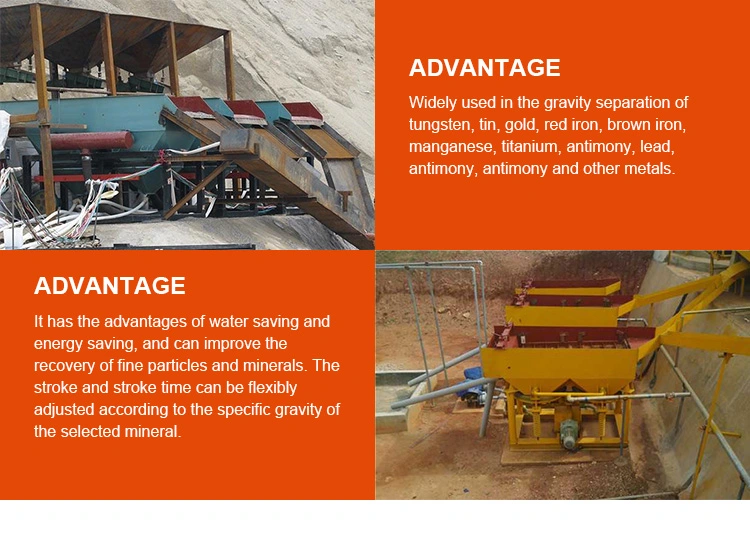

underground copper gold gemstone mining equipment need water to work, and it loosens materials in vertical

alternativewater-flows, and it forms different layers of materials of different densities and discharges both layers from

up and down discharging ports separately. The basic composition of jigger is jigging chambers, also called jigging boxes

and there are screens in each chamber.

Water and raw ore will be fed from one end of the jigger screen, the ore granules will move in the vertical alternative water-flows.

Layers will be formed because of density difference of materials. The minerals with small density will be in the up layer and will

flow together with the up pulp flow while material with bigger density will be in the down layer and will discharged from the down

discharging port as jigging concentrate.

| Model | Jig Room | Stroke Coefficient | Septum | Input Size(mm) | Capacity(t/h) | Water Consumption(t/h) | Power(kw) | Weight(kg) | ||||

| Area(m2) | Raw | Room | Total Area(m2) | Stroke(mm) | Times(mm) | |||||||

| LTP -34/2 | 0.135 | 1 | 2 | 0.27 | 0.58 | 0-25 | 320-420 | 12 | 2-6 | 4-10 | 1.1 | 800 |

| LTA -1010/2 | 1.0 | 1 | 2 | 2.0 | 0.5 | 0-25 | 250-350 | 5 | 5-15 | 10-20 | 2.2 | 2890 |

| LTC -69/2 | 0.54 | 1 | 2 | 1.08 | 0.55 | 0-50 | 220-350 | 8 | 6-9 | 40-60 | 1.5 | 1420 |

| 2LTC-366/8T | 0.2-0.34 | 2 | 8 | 2.16 | 0.68-0.41 | 0-50 | 120-300 | 5 | 3-6 | 20-40 | 1.1x2 | 3570 |

| 2LTC-6109/8T | 0.58-0.86 | 2 | 8 | 5.76 | 0.52-0.35 | 0-50 | 120-300 | 5 | 10-20 | 80-120 | 2.2x2 | 4650 |

| AM-30 | 0.644 | 2 | 2 | 2.574 | 0.47 | 0-50 | 130 | 30 | 10-15 | 100-150 | 3 | 2400 |

--- PRE-SALE SERVICE ---

1.Based on clients' request and budget, GELIN experts will strictly make efficient, reliable solutions accordingly;

2.Mine sample testing is available, we welcome the customer send the sample to you for testing by courier, or, the

customer take the sample to our factory for testing;

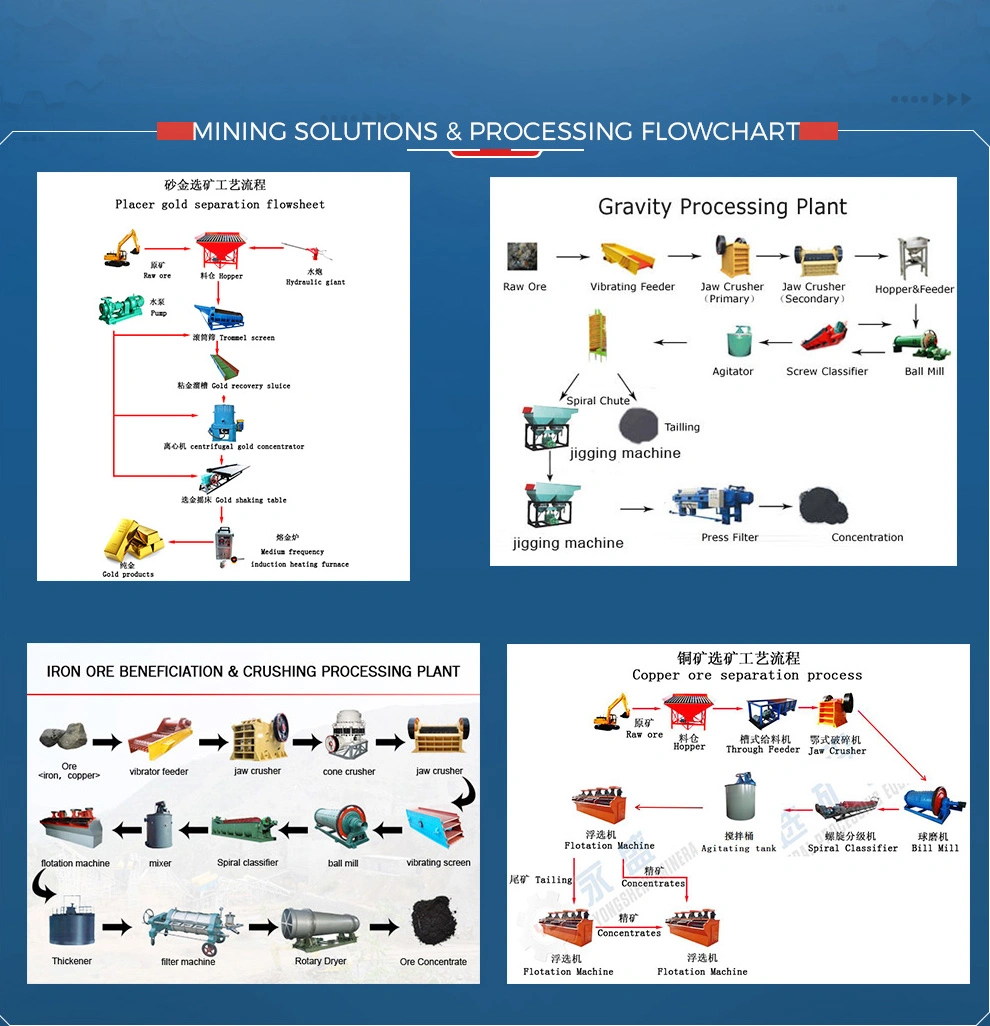

3. Design and provide the complete processing flowchart;

4. Design & manufacturer products according to clients' demands.

--- AFTER-SALE SERVICE ---

1.Pre-check and test the products before delivery;

2.Deliver the whole plant design for our clients which including infrastructure, electrical system and pipeline system design;

3.Trace the status of the shipping until the products received;

4.Prepare required documents to let clients pass custom clearance;

5.Dispatch experts to carry out below service on site:

1) Installation & debug of the machinery

2) Train the first-line operators & technical personnel

3) Carry out any other service clients may need

6. Provide technical exchanging & spare parts for life-long term

--- ONE STOP SOLUTION ---

1.Starting by running the mineral beneficiation experiment. To provide our clients with the best solution accordingly;

2.Besides supply the flowchart design & equipment, we also provide the infrastructure design; Electrical & pipeline system

design, etc. To help our clients complete the design of the whole plant;

3.After the installation, debugging of the equipment, the official production will also be guiding by our experienced engineers on

site, to guarantee the output minerals perfectly meet your demands.

FAQ

Q: What Information should customers give to us in order to let we provide you with efficient & suitable quotation

and assistance.

A:1). What type is the mining? Is it rock stone? or it is sand?

2). If rock stone,What is the general particle size(mm) of the raw ore?

3). What is the handling capacity(tons per hour) you plan to work with?

4).What is the elements of the raw ore? How much percent % of each minerals?

Q: Can we send the mineral samples to your company, let your company run the ore-dressing experiments test for us?

A: Yes, we can run the ore-dressing experiments for our customers. After the test, we will based on the results to give you the reasonable

flowchart, suitable solution and equipments selection. etc.

Q: How long is the warrenty of your equipments? Does your company supply the spare parts?

A: The warranty period of Gelin equipments is one year. And of course we will supply the spare parts for you for life-long time at lowest cost.

Q: If i need the complete mineral processing line. is Gelin able to help us build it?

A: Yes, we can help you combine a complete mineral processing line. and give you related professional advices as long as you need.

There is a rich experience engineer team of us. we had already build many mining projects in China & Overseas. You can believe our quality

and service.

Welcome to visit our factory in your free time!