Copper Ore Benenfication Plant Lab Flotation Cell Machine

copper ore benenfication plant lab flotation cell machine flotation machine is suitable for separating non-ferrous metal

Basic Info

| Model NO. | XCF |

| Material | Carbon Steel |

| Material Feature | Wear-Resisting |

| Certification | ISO9001:2008 |

| Energy Saving | Energy Saving |

| Warranty | 1 Year |

| Color | Multi Color |

| Customized | Customized |

| Condition | New |

| After-sales Service | Installation Guide, Spare Part Supplying |

| Application | Copper Ore, Gold Ore, Lead-Zinc, Coal |

| Transport Package | Nude |

| Specification | XCF/KYF |

| Trademark | ZHONGJIA |

| Origin | Henan, China |

| HS Code | 8474100000 |

| Production Capacity | 100 Set/Year |

Product Description

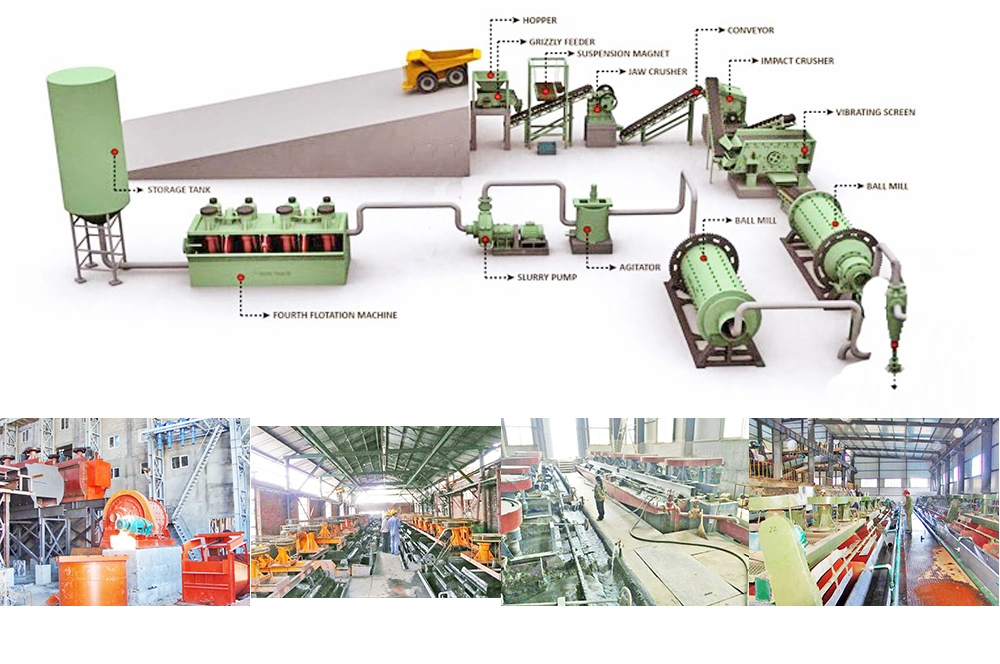

copper ore benenfication plant lab flotation cell machineflotation machine is suitable for separating non-ferrous metals, ferrous metals, precious metals, non-metallic minerals and chemical raw materials and recovering useful minerals.

XCF/KYF flotation cell machine

The impeller section of KYF flotation machine and XCF flotation machine is in the shape of double inverted cone platform, that is, the impeller outline is reduced in two sections from top to bottom, and there are 6-8 backward inclined blades, that is, the blade direction forms a certain included angle with the radius, and the inclined direction is opposite to the forward direction of rotation; A special air distributor is designed in the impeller cavity. The air distributor is circular and simple, and small holes are evenly distributed around it. The stator is divided into four parts, covering the inclined upper part around the impeller and supported on the slot body.

When the ground ore is ground or after grinding, add water and necessary reagents into the slurry through the mixing tank, inject it into the slurry tank to introduce air into the slurry to form a large number of bubbles. Some mineral particles that are not easy to be wetted by water, commonly known as hydrophobic, are attached to the bubbles and float to the slurry surface together with the bubbles to form a mineralized bubble layer, Other mineral particles that are easily wetted by water, commonly known as hydrophilic mineral particles, do not adhere to bubbles, but stay in the pulp to discharge mineralized bubbles containing specific minerals, so as to achieve the purpose of beneficiation. For this reason, SF flotation machine is sometimes called mine flotation machine

Technical parameter

| Type | Volume (m³) | Capacity (m³/min) | Diameter (mm) | line Speed (m/s) | Weight (t) |

| XCF-8 | 8 | 2-8 | 720 | 7.5 | 3.8 |

| XCF-38 | 38 | 8-19 | 1050 | 8.15 | 12.8 |

Company introduction

Our company is a professional manufacturer of complete sets of mineral processing machinery, cement, chemical, building materials and other equipment, with a production history of more than 40 years. Its main products are: Jaw crusher, Hammer crusher, Roller crusher, Impact Crusher, Ball Mill, Rod Mill, Rotary Kiln, Stone Production Line, Sand Production Line, Sand Making Machinery, Mobile Crushing Station, Organic Fertilizer production line, flotation machine, magnetic separator, jig machine, slime dryer, sludge dryer, limestone ash machine, dryer, cooler, pelletizing machine, vibrating screen, automatic sand return spiral classification Machines, high-efficiency and energy-saving flotation machines, mining mixing tanks, feeders, filters, thickeners, lifting conveyors, screw conveyors and other mechanical equipment.

Send to us